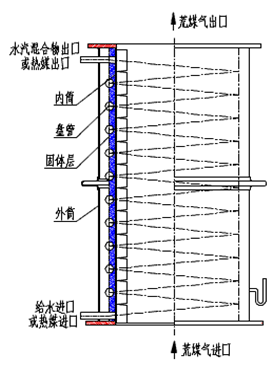

Principle of Ascension Pipe Waste Heat Recovery

Date:

2025-04-16

Technical Advantages of NJHD Stress-Free Helical Coil Structure Ascension Pipe

Safety Assurance: Even if the pressure-bearing component leaks, the medium will not enter the carbonization chamber, ensuring coke oven safety.

Medium-Pressure Steam Generation: Achieves steam pressure ≥4.0 MPa.

High Steam Yield: Produces over 120 kg of steam per ton of coke.

Enhanced Heat Transfer: Straight fins added to the raw gas channel improve heat transfer, raise wall temperature, and prevent tar condensation.

Dual Heat Carrier Options: Supports both water and thermal oil circulation for waste heat recovery.

Stress-Free Helical Coil: Eliminates thermal fatigue, extending equipment lifespan.

Anti-Coking Technology: Thermal barrier agents increase wall temperature, preventing coking; graphite cycle extended to one month (with maintenance).

High Efficiency: Fully replaces tube heating furnaces with 95%+ energy utilization.

Superheating Capability: Steam heated to over 400°C.

System Features

Load Adaptability: Adjusts wall temperature to avoid condensation (30%~120% load range for ovens; 30%~250% for individual pipes).

User-Friendly Control: Simple operation, high reliability, and low labor intensity.

Economic & Environmental Benefits: Integrates with chemical processes, replaces tube furnaces, and reduces emissions.

Flexible Steam Output: Same system supplies both saturated and superheated steam.

Safety

Double-Layer Protection: Leakage detection prevents water ingress into the coke oven.

Emission Control: Maintains wall temperature to eliminate black smoke during lid opening.

Robust Material: Corrosion/wear-resistant inner tube withstands dry firing and system failures.

Stress-Free Durability: Handles extreme and variable operating conditions.

Low Failure Rate: Simplified operation minimizes errors and downtime.

Product center

/

Products

-

Technical Advantages of NJHD Stress-Free Helical Coil Structure Ascension PipeSafety Assurance: Even if the pressure-bearing component leaks, the medium will not enter the carbonization chamber, ensuring coke oven safety.Medium-Pressure Steam Generation: Achieves steam pressure ≥4.0 MPa.High Steam Yield: Produces over 120 kg of steam per ton of coke.Enhanced Heat Transfer: Straight fins added to the raw gas channel improve heat transfer, raise wall temperature, and prevent tar condensation.Dual Heat Carrier Options: Supports both water and thermal oil circulation for waste heat recovery.Stress...

-

-

-