Solutions for Dual Preheating Technology in Blast Furnace Hot Stoves

I. Current Technical Status at Home and Abroad

Challenges in Conventional Domestic Technology:

1. Low-Temperature Corrosion from Flue Gas and Blast Furnace Gas (BFG): BFG contains acidic components (Cl⁻, S, etc.), leading to the precipitation of strong acidic water at low temperatures. This causes wet ash clogging, corrodes heat exchangers, resulting in equipment perforation, gas leakage, and safety hazards.

2. Low-temperature corrosion of flue gas: If the wall temperature of the heat transfer surface at the flue gas outlet is too low, it can cause low-temperature acid dew point corrosion on the flue gas side, condensation-induced ash blockage, and damage to the heat transfer surface.

3. High-Temperature Damage: Heat pipe heat exchangers are prone to tube bursts. Plate/Shell-and-tube heat exchangers suffer from weld seam tearing due to uneven thermal expansion.

4. Rapid Performance Degradation: For example, with heat pipe systems, heat transfer efficiency degrades by ≥5% annually, with an equipment lifespan of only 3-5 years.

5. Severe Gas Leakage: When plate heat exchangers are used, CO leakage increases significantly after long-term operation, leading to annual losses amounting to millions of dollors.

6. Regardless of using heat pipe or plate heat exchangers, replacement is required every 3~5 years.

Current International Technology:

Utilizes forced circulation technology with a heat transfer fluid (HTF, intermediate circulating medium), achieving an equipment lifespan exceeding 10 years and stable heat exchange performance.

However, the low-temperature section still requires periodic offline cleaning, and the modular design lacks sufficient flexibility.

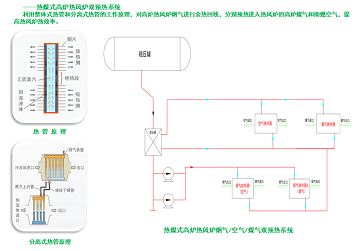

II. Our Solution ------ "STERM" Intelligent Dual Preheating Technology

An HTF (Heat Transfer Fluid) based heat exchange technology characterized by Smart control, precise Temperature management, Effective performance, and Reliable operation, utilizing a circulating Medium.

Core Technology:

Using a heat transfer fluid (HTF, intermediate circulating medium) as the heat transfer medium, combined with intelligent temperature control and modular design, to overcome the pain points of traditional technologies, achieving safe, efficient, and long-life waste heat recovery.

Technical Advantages:

1. Comprehensive Corrosion Protection and Efficient Soot Cleaning

Intelligent Temperature Control: Real-time adjustment of the intermediate circulating medium temperature ensures the heat exchange surface wall temperature remains above the acid dew point, completely preventing low-temperature condensation corrosion.

Online Cleaning: The BFG inlet section employs corrosion-resistant materials + modular spray devices, enabling rapid ash removal during BF shutdown periods, superior to the offline cleaning mode used abroad. (Online cleaning of the BFG low-temperature section every 2-4 months).

2. Stable Performance, Lower Resistance

Long-Term Heat Exchange Efficiency: Annual efficiency degradation ≤2°C, service life exceeds 10 years, far surpassing the domestic standard of 3-5 years.

Optimized Flow Resistance: Flow resistance in flue gas, BFG, and air ducts is reduced by 30% compared to conventional heat exchangers, significantly outperforming plate heat exchangers, thereby reducing system energy consumption.

3. Intelligent Safety and Flexible Adaptation

Separated Design Preventing Leakage: Independent flow paths for flue gas, BFG, and air eliminate the risk of cross-leakage.

Over-Temperature Self-Adaptation: Supports flue gas over-temperature conditions up to 400°C without manual intervention; the high-temperature resistance of the HTF (thermal oil) ensures system safety during power outages.

Modular Structure: Vulnerable areas feature independent module design, allowing for partial replacement, reducing maintenance costs by 50%.

4. Dual Benefits: Economic and Environmental

Significant Energy Savings: Taking a 2500m³ BF hot stove as an example, exhaust gas temperature is reduced below 130°C, yielding 10-year energy savings benefits of 20 million RMB (Based on BFG calorific value 750 kCal/Nm³, price 0.09 RMB/Nm³).

Emission Reduction & Efficiency Gain: Over 60,000 tons of CO₂ reduced over 10 years, contributing to the "Dual Carbon" goals.

III. Shortcomings of "STERM" Intelligent Dual Preheating Technology

Higher Initial Investment: System complexity is higher than traditional technologies, but the comprehensive 10-year return can reach 3-5 times the initial investment.

Power Consumption Cost: For a 2500m³ BF hot stove, annual electricity consumption for the circulation pump is approximately 14,000 USD, accounting for only ~0.5% of the energy savings benefit.

IV. Summary

Our "STERM" technology, centered on HTF circulation and integrating intelligent temperature control, modular design, and low-resistance structure, comprehensively solves the traditional dual preheating challenges of corrosion, leakage, and short lifespan. It achieves over 30% improvement in comprehensive energy efficiency. Its high safety, long service life, and low-carbon characteristics provide an exemplary solution for the steel industry's pursuit of ultimate energy efficiency goals.